Regarding cost comparison of the systems described the lowest cost system is hydrophilic, but there is a degree of site work required to get the system installed, the cost for reworking joints and placing the hydrophilic strip is often not included in the metre rate of the system when compared to the active systems.

The PVC tape, while it has higher cost/m, there is a degree of work needed to form the joints need to allow the arrangement to be placed on site. A specialist will also be required on site to create joints in-situ, there is also the cost associated with the workmanship. The coated metal sheet, on the other hand, is of a relative cost level to the PVC system in the plain roll without specialist corners.

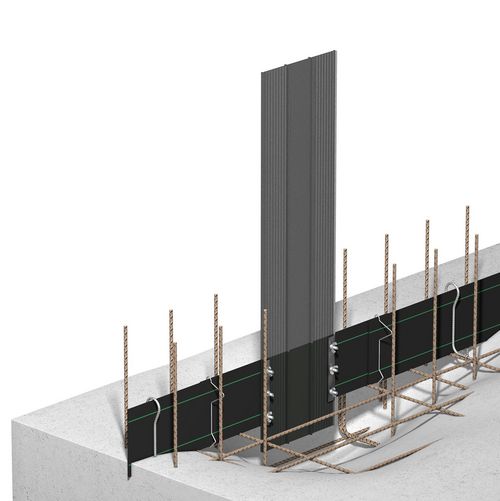

The coated steel system has no special requirements or needs for advance orders to be placed for individual joints, as joints can be formed on site. Since joints can be formed in place since there are no requirements for a specialist to be in attendance at the site level as it is a very low skill system and can be easily installed and planed at the site level. This allows the planning of basement works to be adjusted with ease by the contractor, in the knowledge the steel coasted system will be fully active once the concrete has been placed.

The advances in sealing technology systems with the introduction of the coated steel sheet provide a robust, cost-effective solution to provide rugged basement solutions to meet the ever-increasing demands of the client performance specifications. The de-skilling of sites puts more pressure on getting it right the first time. Advances in product technology will allow this to happen.

Contact us for further information